| Availability: | |

|---|---|

| Quantity: | |

DNYF1.0

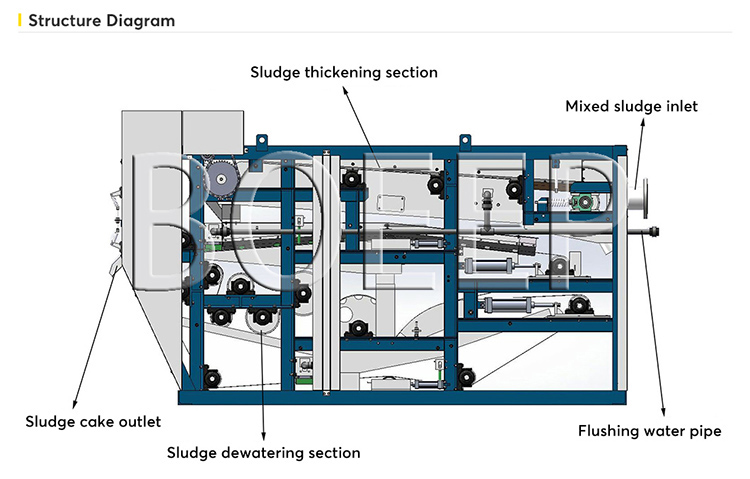

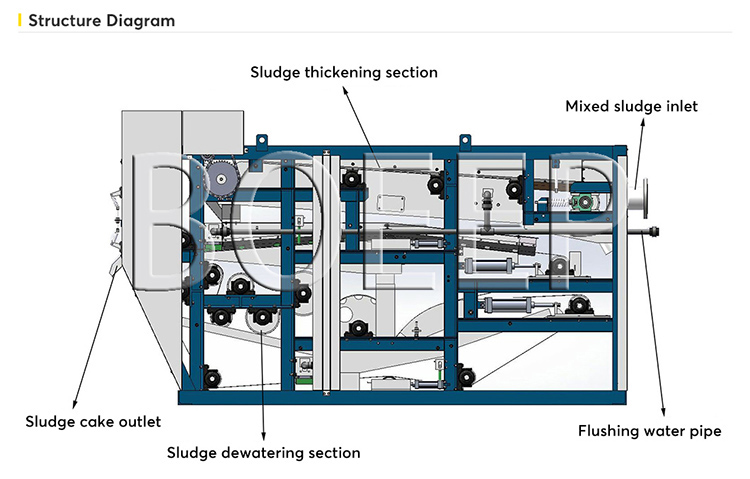

The BOEEP Belt Filter Press for Sludge Dewatering Machine offers an innovative solution that seamlessly integrates sludge concentration and dewatering in a single, efficient system. Featuring advanced belt filter press technology, including high-pressure roll structures and polyester monofilament filter belts, this machine boasts a significantly larger treatment capacity and lower sludge cake moisture content compared to traditional systems. Designed for reliability and versatility, the Belt Filter Press is ideal for processing various sludge types, including A/O residual sludge, making it one of the most dependable options in the market.

The BOEEP Belt Filter Press for Sludge Dewatering combines the critical functions of sludge concentration and dewatering into a single unit. Utilizing a high-duty press structure with multiple press rolls and high-pressure rollers, this belt filter press enhances sludge treatment capacity and minimizes moisture content in the sludge cake. As a significant upgrade over traditional gravity belt filter presses, this advanced dewatering technology ensures superior performance tailored for industrial applications.

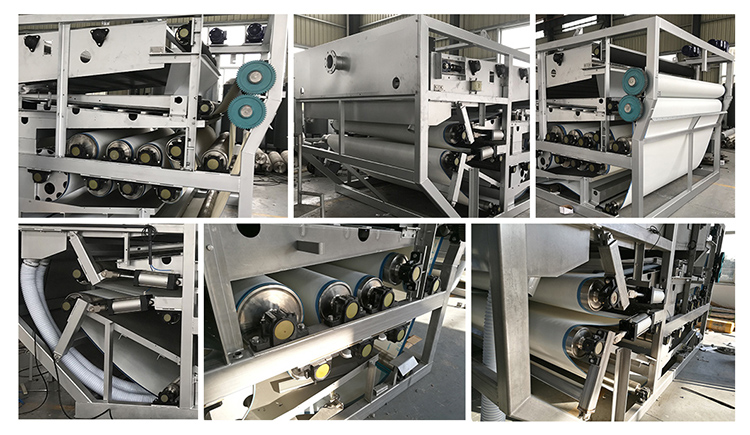

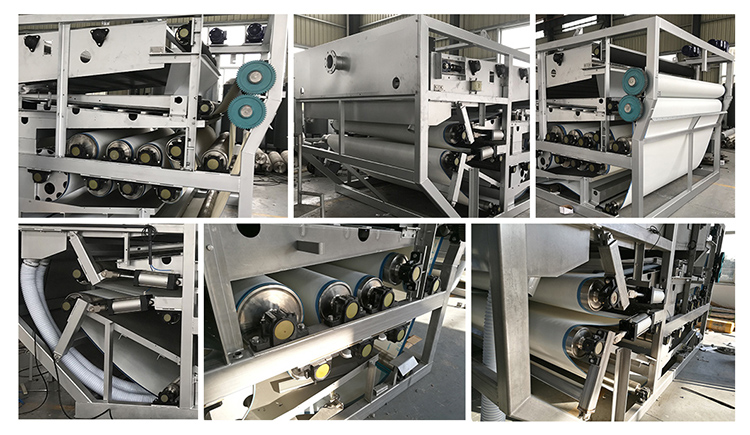

This belt filter press incorporates a fully enclosed design that promotes safe and clean operations. The flexible filter belt correction device automatically adjusts when the filter belt deviates from the center, ensuring optimal operation. This automatic correction function enhances precision while reducing maintenance requirements. The filter belt, made from high-strength polyester monofilament, offers exceptional corrosion resistance, permeability, and a smooth surface, contributing to higher solid recovery rates and improved overall efficiency.

The Belt Filter Press is equipped with a robust washing system that ensures thorough cleaning of the filter belt via a spray pipe and replaceable nozzles. This integrated backwash filter simplifies maintenance, making cleaning and upkeep more convenient than ever. Furthermore, the BOEEP Belt Filter Press meets JB/T8102-1999 standards for both empty load and load tests, guaranteeing optimal operation across diverse industrial settings.

Flexible Filter Belt Correction: The automatic correction device effectively realigns the filter belt when it deviates from the center by up to 15 mm. The system is adjustable according to actual operation conditions, ensuring reliable and consistent performance.

Advanced Washing System: The dewatering machine features a comprehensive washing system comprising a spray pipe and nozzles, covering the filter belt's width. Each nozzle is replaceable and designed to maintain sealing properties, preventing splashing and contamination of the sludge cake.

High-Quality Filter Belt: The filter belt is constructed from polyester monofilament, known for its high strength, corrosion resistance, and excellent permeability. Its smooth surface minimizes blockage and maximizes solid recovery rates during the sludge dewatering process.

Compliance with Standards: The empty load test of the dewatering machine adheres to the requirements of JB/T8102-1999, ensuring that it meets industry standards for both empty and loaded operations.

Product Details

Regularly clean the filter belt using the built-in washing system to ensure optimal performance.

Inspect and replace nozzles as needed to maintain efficient cleaning and operation.

Monitor the automatic correction system to ensure proper alignment of the filter belt during operation.

Conduct periodic load tests according to JB/T8102-1999 standards to guarantee continued efficiency and performance of the belt filter press.

Q: What types of sludge can this machine handle?

A: The BOEEP Belt Filter Press is designed to accommodate a wide range of sludge types, including A/O residual sludge and various industrial sludge applications.

Q: How does the machine compare to traditional belt filter presses?

A: This belt filter press offers higher treatment capacity and significantly lower moisture content in the sludge cake due to its innovative multiple press roll design and high-pressure rollers.

Q: Is the machine easy to maintain?

A: Yes, the design of the belt filter press is fully enclosed and equipped with an efficient washing system and automatic correction devices, making maintenance straightforward and efficient.

Q: Can the machine be customized?

A: Absolutely! The specifications of the Belt Filter Press can be adjusted based on customer needs, accommodating different sludge types and treatment capacities for optimal performance.

With BOEEP’s Belt Filter Press for Sludge Dewatering Machine, facilities can achieve efficient and reliable sludge management, enhancing their overall wastewater treatment processes while minimizing environmental impact.

The BOEEP Belt Filter Press for Sludge Dewatering Machine offers an innovative solution that seamlessly integrates sludge concentration and dewatering in a single, efficient system. Featuring advanced belt filter press technology, including high-pressure roll structures and polyester monofilament filter belts, this machine boasts a significantly larger treatment capacity and lower sludge cake moisture content compared to traditional systems. Designed for reliability and versatility, the Belt Filter Press is ideal for processing various sludge types, including A/O residual sludge, making it one of the most dependable options in the market.

The BOEEP Belt Filter Press for Sludge Dewatering combines the critical functions of sludge concentration and dewatering into a single unit. Utilizing a high-duty press structure with multiple press rolls and high-pressure rollers, this belt filter press enhances sludge treatment capacity and minimizes moisture content in the sludge cake. As a significant upgrade over traditional gravity belt filter presses, this advanced dewatering technology ensures superior performance tailored for industrial applications.

This belt filter press incorporates a fully enclosed design that promotes safe and clean operations. The flexible filter belt correction device automatically adjusts when the filter belt deviates from the center, ensuring optimal operation. This automatic correction function enhances precision while reducing maintenance requirements. The filter belt, made from high-strength polyester monofilament, offers exceptional corrosion resistance, permeability, and a smooth surface, contributing to higher solid recovery rates and improved overall efficiency.

The Belt Filter Press is equipped with a robust washing system that ensures thorough cleaning of the filter belt via a spray pipe and replaceable nozzles. This integrated backwash filter simplifies maintenance, making cleaning and upkeep more convenient than ever. Furthermore, the BOEEP Belt Filter Press meets JB/T8102-1999 standards for both empty load and load tests, guaranteeing optimal operation across diverse industrial settings.

Flexible Filter Belt Correction: The automatic correction device effectively realigns the filter belt when it deviates from the center by up to 15 mm. The system is adjustable according to actual operation conditions, ensuring reliable and consistent performance.

Advanced Washing System: The dewatering machine features a comprehensive washing system comprising a spray pipe and nozzles, covering the filter belt's width. Each nozzle is replaceable and designed to maintain sealing properties, preventing splashing and contamination of the sludge cake.

High-Quality Filter Belt: The filter belt is constructed from polyester monofilament, known for its high strength, corrosion resistance, and excellent permeability. Its smooth surface minimizes blockage and maximizes solid recovery rates during the sludge dewatering process.

Compliance with Standards: The empty load test of the dewatering machine adheres to the requirements of JB/T8102-1999, ensuring that it meets industry standards for both empty and loaded operations.

Product Details

Regularly clean the filter belt using the built-in washing system to ensure optimal performance.

Inspect and replace nozzles as needed to maintain efficient cleaning and operation.

Monitor the automatic correction system to ensure proper alignment of the filter belt during operation.

Conduct periodic load tests according to JB/T8102-1999 standards to guarantee continued efficiency and performance of the belt filter press.

Q: What types of sludge can this machine handle?

A: The BOEEP Belt Filter Press is designed to accommodate a wide range of sludge types, including A/O residual sludge and various industrial sludge applications.

Q: How does the machine compare to traditional belt filter presses?

A: This belt filter press offers higher treatment capacity and significantly lower moisture content in the sludge cake due to its innovative multiple press roll design and high-pressure rollers.

Q: Is the machine easy to maintain?

A: Yes, the design of the belt filter press is fully enclosed and equipped with an efficient washing system and automatic correction devices, making maintenance straightforward and efficient.

Q: Can the machine be customized?

A: Absolutely! The specifications of the Belt Filter Press can be adjusted based on customer needs, accommodating different sludge types and treatment capacities for optimal performance.

With BOEEP’s Belt Filter Press for Sludge Dewatering Machine, facilities can achieve efficient and reliable sludge management, enhancing their overall wastewater treatment processes while minimizing environmental impact.