| Availability: | |

|---|---|

| Quantity: | |

MYDL401

The Mobile Sludge Treatment Unit by BOEEP is a state-of-the-art, portable solution designed for effective onsite sludge removal and dewatering. This mobile sludge treatment system features an integrated screw press, polymer preparation unit, sludge pump, and conveyor, ensuring efficient mechanical screening for both municipal and industrial wastewater applications. Its compact, fully enclosed design minimizes odor and noise, making it ideal for small-scale sewage facilities. With automated controls for continuous operation, this unit enhances overall operational efficiency while reducing maintenance needs and environmental impact.

The Mobile Sludge Treatment Unit provides a highly mobile and effective solution for onsite sludge treatment and dewatering. Its portable design allows for easy transportation and quick setup at various wastewater treatment locations, making it perfect for temporary or small-scale projects. Equipped with an integrated screw press system, this unit significantly enhances solid-liquid separation, improving the overall wastewater treatment process. This cost-effective unit is suitable for a wide range of applications, including municipal, environmental, and industrial sectors such as food and beverage, chemical industry, and more.

At the core of the Mobile Sludge Treatment Unit is its advanced screw press dewatering technology. The unit effectively performs primary wastewater treatment, drawing sludge from the treatment tank into a mixing chamber where it undergoes flocculation. The sludge is then directed into the screw press for efficient dewatering, producing a dry sludge cake for disposal while recycling the filtrate back into the treatment process. Its compact and fully enclosed design prevents odors from escaping, and the low noise levels create a cleaner and quieter working environment.

Portable System for On-Site Sewage Treatment: Easily transportable for effective sludge management across different locations.

Integrated Screw Press for Sludge Dewatering: Ensures high-efficiency solid-liquid separation, critical for mechanical screening in wastewater treatment.

Fully Enclosed, Odor-Controlled Design: Reduces odor emissions during operation, enhancing the working environment.

Low Power Consumption and Minimal Noise: Operates quietly while conserving energy, suitable for municipal applications.

Automated Controls for Continuous Operation: Streamlines the process and reduces the need for manual labor in sludge treatment.

Ideal for Small-Scale and Temporary Treatment Projects: Perfect for a range of industries, including automobile, electronics, pharmacy, and livestock processing.

Fully Enclosed with Minimal Odor: The system’s design contains unpleasant odors, ensuring a more pleasant working atmosphere during sludge treatment operations.

Low Power Consumption and Noise Levels: The screw press operates at low speeds, reducing energy consumption and operational noise, which is critical for environmental applications.

Compact and Easy to Maintain: The unit features a low maintenance design with fewer wearing parts, allowing for straightforward operation and quick maintenance, which reduces downtime.

Mobile and Convenient: Designed for easy relocation, this unit is ideal for temporary projects or small-scale wastewater treatment facilities in space-constrained areas.

Continuous and Automated Operation: The unit features full automation for polymer preparation, sludge pumping, and cake discharge, ensuring continuous, uninterrupted operation with minimal manual intervention.

Cost-Efficient: Its energy-saving design, low operational costs, and minimal water usage make it an economical choice for effective sludge dewatering and wastewater treatment.

High mobility: the whole equipment adopts containerized design, which can be easily moved and transported to different locations, suitable for emergency, temporary or highly mobile sewage treatment needs.

Plug and play: the equipment adopts modularized design, simple and fast installation, without complex infrastructure construction, can be quickly put into use.

Wide range of application: applicable to urban sewage, industrial wastewater, rural sewage and other types of sewage treatment. Specifications can be customized according to the size of the treatment capacity.

Good treatment effect: adopting advanced biofilm, flocculation and precipitation sewage treatment process, the effluent water quality is stable and can meet the relevant emission standards.

High degree of automation: the equipment has automatic monitoring and remote control functions, convenient operation and management.

Energy saving and environmental protection: the equipment adopts energy-saving design, low energy consumption, low operating costs. No secondary pollution, in line with environmental requirements.

Small footprint: the entire equipment using containerized design, small footprint, easy to install and use in space-constrained areas.

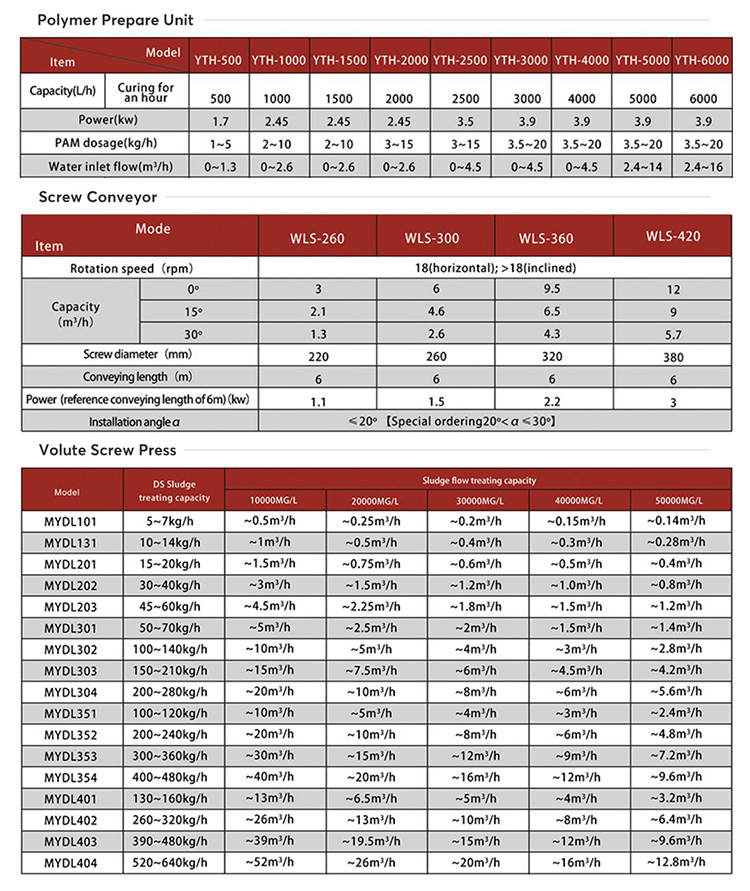

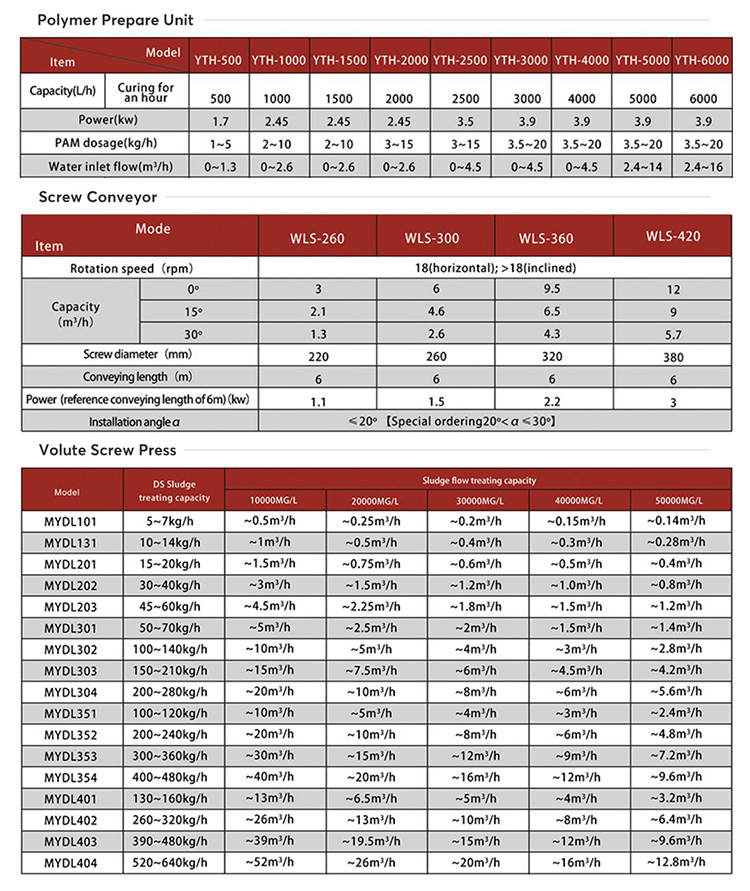

Model Choice

To ensure optimal performance of the Mobile Sludge Treatment Unit, conduct regular inspections and maintenance. Check the screw press for wear and tear and clean any buildup in the mixing chamber. Adhere to the manufacturer’s guidelines for routine maintenance tasks, including replacing polymer chemicals and checking system controls. This low maintenance design enhances the longevity and efficiency of the unit.

Setup: Transport the unit to the desired location and ensure it is on a stable, level surface.

Connect: Hook up the required input and output connections for sludge inflow and treated water discharge.

Operation: Start the system using the automated controls. Monitor the process through the control panel to ensure proper flocculation and dewatering.

Maintenance: Perform regular checks to ensure the system operates efficiently, carrying out necessary maintenance tasks as per the guidelines.

Q: What applications can the Mobile Sludge Treatment Unit serve?

A: This unit is suitable for various applications, including municipal wastewater treatment, industrial wastewater, food and beverage, oil and gas, chemical industry, and more.

Q: How does the sludge dewatering process work?

A: The unit employs an integrated screw press to separate solids from liquids in the sludge. The sludge is flocculated and passed through the press to produce a dewatered sludge cake for disposal.

Q: Is the unit easy to operate?

A: Yes, the Mobile Sludge Treatment Unit features automated controls that make it user-friendly and require minimal manual intervention.

Q: How does the unit handle odor and noise?

A: The fully enclosed design minimizes odor emissions, while the low-speed operation of the screw press ensures low noise levels during operation.

With BOEEP's Mobile Sludge Treatment Unit, facilities can efficiently manage sludge dewatering and wastewater treatment, ensuring reliable performance across multiple treatment sites while minimizing environmental impact. BOEEP is dedicated to creating value for all stakeholders while promoting sustainable development and effective wastewater solutions.

In general, this mobile container-type sewage treatment equipment with mobile and flexible, ready to use, high processing efficiency, energy saving and environmental protection and many other advantages, widely used in emergency sewage treatment, temporary construction site treatment, rural sewage treatment and other fields!

The Mobile Sludge Treatment Unit by BOEEP is a state-of-the-art, portable solution designed for effective onsite sludge removal and dewatering. This mobile sludge treatment system features an integrated screw press, polymer preparation unit, sludge pump, and conveyor, ensuring efficient mechanical screening for both municipal and industrial wastewater applications. Its compact, fully enclosed design minimizes odor and noise, making it ideal for small-scale sewage facilities. With automated controls for continuous operation, this unit enhances overall operational efficiency while reducing maintenance needs and environmental impact.

The Mobile Sludge Treatment Unit provides a highly mobile and effective solution for onsite sludge treatment and dewatering. Its portable design allows for easy transportation and quick setup at various wastewater treatment locations, making it perfect for temporary or small-scale projects. Equipped with an integrated screw press system, this unit significantly enhances solid-liquid separation, improving the overall wastewater treatment process. This cost-effective unit is suitable for a wide range of applications, including municipal, environmental, and industrial sectors such as food and beverage, chemical industry, and more.

At the core of the Mobile Sludge Treatment Unit is its advanced screw press dewatering technology. The unit effectively performs primary wastewater treatment, drawing sludge from the treatment tank into a mixing chamber where it undergoes flocculation. The sludge is then directed into the screw press for efficient dewatering, producing a dry sludge cake for disposal while recycling the filtrate back into the treatment process. Its compact and fully enclosed design prevents odors from escaping, and the low noise levels create a cleaner and quieter working environment.

Portable System for On-Site Sewage Treatment: Easily transportable for effective sludge management across different locations.

Integrated Screw Press for Sludge Dewatering: Ensures high-efficiency solid-liquid separation, critical for mechanical screening in wastewater treatment.

Fully Enclosed, Odor-Controlled Design: Reduces odor emissions during operation, enhancing the working environment.

Low Power Consumption and Minimal Noise: Operates quietly while conserving energy, suitable for municipal applications.

Automated Controls for Continuous Operation: Streamlines the process and reduces the need for manual labor in sludge treatment.

Ideal for Small-Scale and Temporary Treatment Projects: Perfect for a range of industries, including automobile, electronics, pharmacy, and livestock processing.

Fully Enclosed with Minimal Odor: The system’s design contains unpleasant odors, ensuring a more pleasant working atmosphere during sludge treatment operations.

Low Power Consumption and Noise Levels: The screw press operates at low speeds, reducing energy consumption and operational noise, which is critical for environmental applications.

Compact and Easy to Maintain: The unit features a low maintenance design with fewer wearing parts, allowing for straightforward operation and quick maintenance, which reduces downtime.

Mobile and Convenient: Designed for easy relocation, this unit is ideal for temporary projects or small-scale wastewater treatment facilities in space-constrained areas.

Continuous and Automated Operation: The unit features full automation for polymer preparation, sludge pumping, and cake discharge, ensuring continuous, uninterrupted operation with minimal manual intervention.

Cost-Efficient: Its energy-saving design, low operational costs, and minimal water usage make it an economical choice for effective sludge dewatering and wastewater treatment.

High mobility: the whole equipment adopts containerized design, which can be easily moved and transported to different locations, suitable for emergency, temporary or highly mobile sewage treatment needs.

Plug and play: the equipment adopts modularized design, simple and fast installation, without complex infrastructure construction, can be quickly put into use.

Wide range of application: applicable to urban sewage, industrial wastewater, rural sewage and other types of sewage treatment. Specifications can be customized according to the size of the treatment capacity.

Good treatment effect: adopting advanced biofilm, flocculation and precipitation sewage treatment process, the effluent water quality is stable and can meet the relevant emission standards.

High degree of automation: the equipment has automatic monitoring and remote control functions, convenient operation and management.

Energy saving and environmental protection: the equipment adopts energy-saving design, low energy consumption, low operating costs. No secondary pollution, in line with environmental requirements.

Small footprint: the entire equipment using containerized design, small footprint, easy to install and use in space-constrained areas.

Model Choice

To ensure optimal performance of the Mobile Sludge Treatment Unit, conduct regular inspections and maintenance. Check the screw press for wear and tear and clean any buildup in the mixing chamber. Adhere to the manufacturer’s guidelines for routine maintenance tasks, including replacing polymer chemicals and checking system controls. This low maintenance design enhances the longevity and efficiency of the unit.

Setup: Transport the unit to the desired location and ensure it is on a stable, level surface.

Connect: Hook up the required input and output connections for sludge inflow and treated water discharge.

Operation: Start the system using the automated controls. Monitor the process through the control panel to ensure proper flocculation and dewatering.

Maintenance: Perform regular checks to ensure the system operates efficiently, carrying out necessary maintenance tasks as per the guidelines.

Q: What applications can the Mobile Sludge Treatment Unit serve?

A: This unit is suitable for various applications, including municipal wastewater treatment, industrial wastewater, food and beverage, oil and gas, chemical industry, and more.

Q: How does the sludge dewatering process work?

A: The unit employs an integrated screw press to separate solids from liquids in the sludge. The sludge is flocculated and passed through the press to produce a dewatered sludge cake for disposal.

Q: Is the unit easy to operate?

A: Yes, the Mobile Sludge Treatment Unit features automated controls that make it user-friendly and require minimal manual intervention.

Q: How does the unit handle odor and noise?

A: The fully enclosed design minimizes odor emissions, while the low-speed operation of the screw press ensures low noise levels during operation.

With BOEEP's Mobile Sludge Treatment Unit, facilities can efficiently manage sludge dewatering and wastewater treatment, ensuring reliable performance across multiple treatment sites while minimizing environmental impact. BOEEP is dedicated to creating value for all stakeholders while promoting sustainable development and effective wastewater solutions.

In general, this mobile container-type sewage treatment equipment with mobile and flexible, ready to use, high processing efficiency, energy saving and environmental protection and many other advantages, widely used in emergency sewage treatment, temporary construction site treatment, rural sewage treatment and other fields!