| Availability: | |

|---|---|

| Quantity: | |

MYDL401

BOEEP

MYDL

Product Description of Volute Screw Press Separator

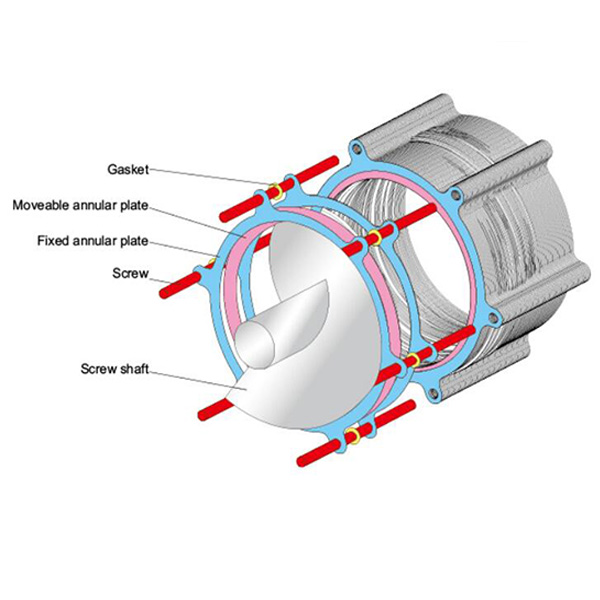

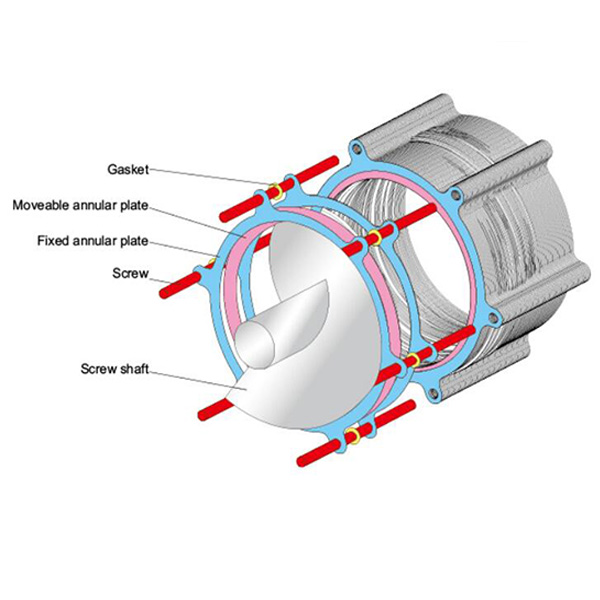

BOEEP volute screw press separator is a new type of solide-liquid separation device which uses the screw extrusion priciple to reache the goal of dewatering sludge by the powerful extrusion pressure of changing the screw diameter and distance along with the tiny spacing between moveable and fixed annular plates.

Overall Structure of Volute Screw Press Separator

BOEEP volute screw press separator is composed of screw body, driving device, filtrate receiver, mixing system and frame. There are 3 parts constitutes the main body of volute screw press dehydrator. They are fixed ring, moveable ring and the screw shaft which runs through the main body. The former part undertakes the task of concentration and the latter part assumes the task of dehydration. It can thicken and dewater sludge in one chamber and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive function.

Working Principle of Volute Screw Press Separator The main body of volute press sludge dewatering machine is made of multiple fixed annular plates and moveable annular plates with the screw shaft running through it. The front part is thickening section and the ending part is dewatering section. It can thicken and dewater sludge in one box. The volute press sludge dehydrator has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model. |

Sludge will be transported to the dewatering part after being thckened in the thickening part. In the advancing progress, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the clogging of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Flow Chart of Volute Screw Press Separator

Application of Volute Screw Press Separator

The volute screw press separator can be widely used to dewater sludge of municipal administration wastewater, food, drink, slaughtering and breeding, printing, petrochemical engineering, papermaking, tannery and pharmaceutical. Innovative structure design makes it possible that the device can be used for all kinds of sludge with high or low density, especially the sludge with oil, and it can be named the invincible opponent to dewater the sludge with oil.

Features of Volute Screw Press Separator

1-It can be widely used in industry and municipal wastewater treatment.

2-The device is anti-clogging.

3-Operation continuously and automatically.

4-Operation costs can be saved.

5-No secondary pollution.

6-Flexible and durable frame.

7-Saving engineering investment.

8-Improving phosphorus removal function.

Technical Parameters of Volute Screw Press Separator

| Parameter | |

| Type:MYDL401 | Dimension:L4680×W1345×H2100(mm) |

| Solid content:10000~50000mg/L | Capacity:130-160kgds/h |

| Power:2.6kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:80L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:2800kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ400×3255(mm) | Dimension:L850×W850×H1355(mm) |

| Quantity:1 | Volume:About 980L |

| Material:Plate: SUS304/ Screw Shaft: SUS30 | Material:SS304 |

| Motor Power:1.5kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Model Choice of Volute Screw Press Separator

Product Details of Volute Screw Press Separator

Object Site of Volute Screw Press Separator

Product Description of Volute Screw Press Separator

BOEEP volute screw press separator is a new type of solide-liquid separation device which uses the screw extrusion priciple to reache the goal of dewatering sludge by the powerful extrusion pressure of changing the screw diameter and distance along with the tiny spacing between moveable and fixed annular plates.

Overall Structure of Volute Screw Press Separator

BOEEP volute screw press separator is composed of screw body, driving device, filtrate receiver, mixing system and frame. There are 3 parts constitutes the main body of volute screw press dehydrator. They are fixed ring, moveable ring and the screw shaft which runs through the main body. The former part undertakes the task of concentration and the latter part assumes the task of dehydration. It can thicken and dewater sludge in one chamber and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive function.

Working Principle of Volute Screw Press Separator The main body of volute press sludge dewatering machine is made of multiple fixed annular plates and moveable annular plates with the screw shaft running through it. The front part is thickening section and the ending part is dewatering section. It can thicken and dewater sludge in one box. The volute press sludge dehydrator has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model. |

Sludge will be transported to the dewatering part after being thckened in the thickening part. In the advancing progress, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the clogging of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Flow Chart of Volute Screw Press Separator

Application of Volute Screw Press Separator

The volute screw press separator can be widely used to dewater sludge of municipal administration wastewater, food, drink, slaughtering and breeding, printing, petrochemical engineering, papermaking, tannery and pharmaceutical. Innovative structure design makes it possible that the device can be used for all kinds of sludge with high or low density, especially the sludge with oil, and it can be named the invincible opponent to dewater the sludge with oil.

Features of Volute Screw Press Separator

1-It can be widely used in industry and municipal wastewater treatment.

2-The device is anti-clogging.

3-Operation continuously and automatically.

4-Operation costs can be saved.

5-No secondary pollution.

6-Flexible and durable frame.

7-Saving engineering investment.

8-Improving phosphorus removal function.

Technical Parameters of Volute Screw Press Separator

| Parameter | |

| Type:MYDL401 | Dimension:L4680×W1345×H2100(mm) |

| Solid content:10000~50000mg/L | Capacity:130-160kgds/h |

| Power:2.6kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:80L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:2800kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ400×3255(mm) | Dimension:L850×W850×H1355(mm) |

| Quantity:1 | Volume:About 980L |

| Material:Plate: SUS304/ Screw Shaft: SUS30 | Material:SS304 |

| Motor Power:1.5kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Model Choice of Volute Screw Press Separator

Product Details of Volute Screw Press Separator

Object Site of Volute Screw Press Separator