| Availability: | |

|---|---|

| Quantity: | |

ZDY1.5

BOEEP

ZDY

Product Introduction

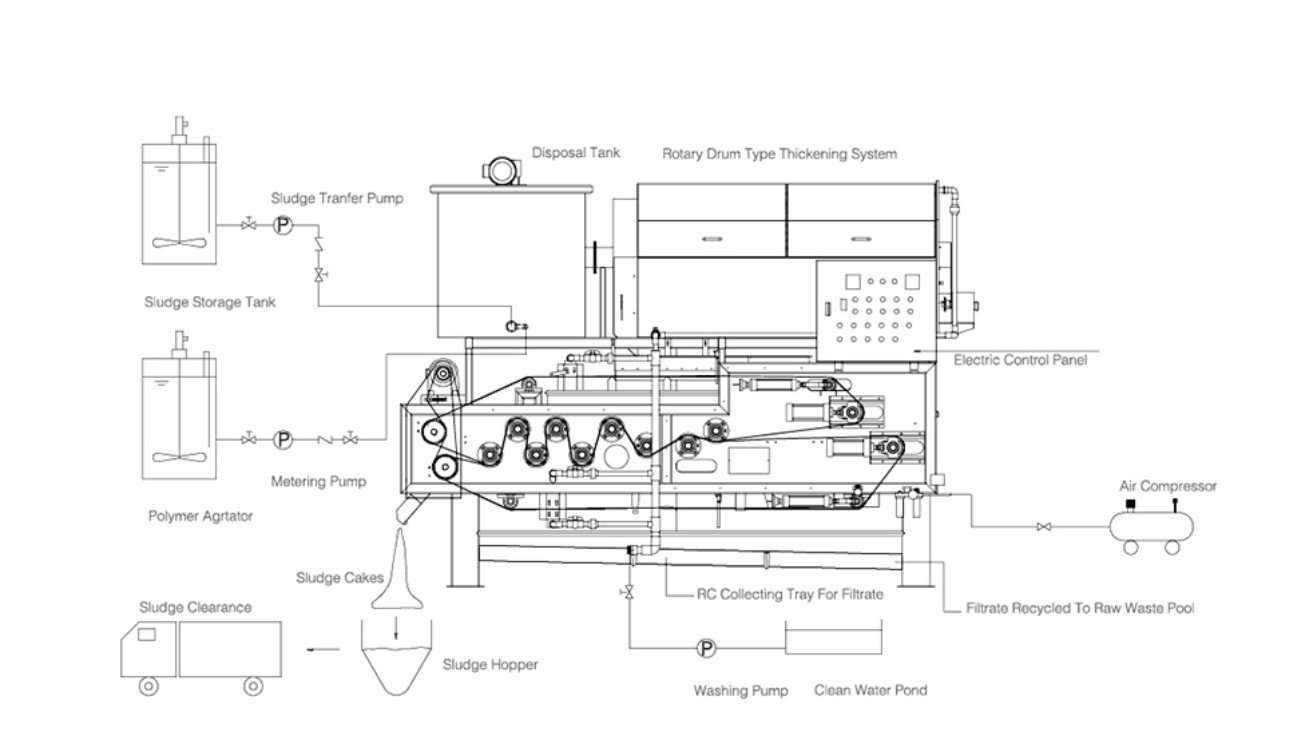

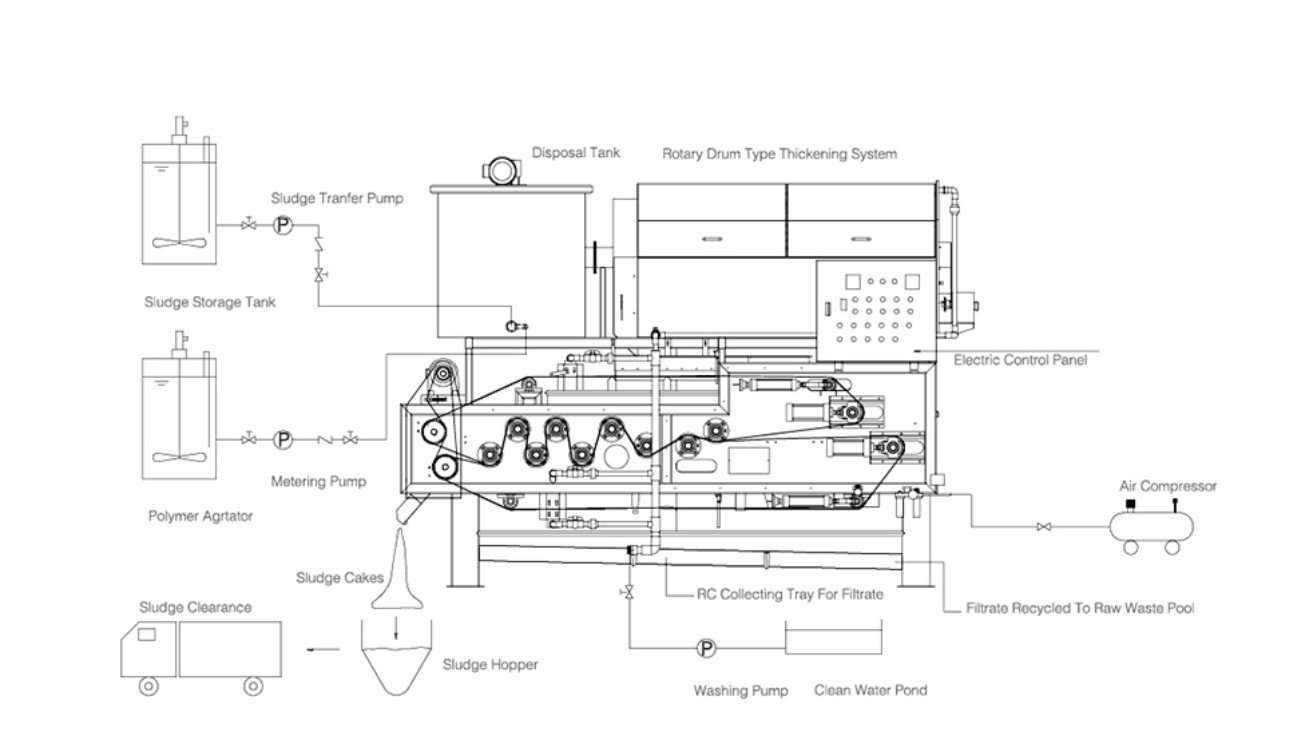

BOEEP belt press dewatering machine has two part. One part is the pre-thickening part is a rotary drum, which has the function of concentration. The other part is belt press part, which completes the dehydration task. This machine is mainly used for processing the sludge which is not concentrated in the thickening pool (such as A/O residual sludge).

Structure & Working Principle

Features

The principal part adopts stainless steel as its material and possesses high strength for it is rust-less.

The filter cloth imported from Germany, which provides the best performance and long service life.

Automatic cylinder deviation correction system effectively prevents filter cloth deviation. The safety alarm device and limit deviation controlling improve filter cloth life and reduce maintenance costs.

Great product capability, good washing effect, flexible operation, low containing moisture in cake.

Low energy consumption, high efficiency, low revolutions, low noise.

Safety system monitors the entire working environment, and automatic stopping devices satisfies the need of operation security.

Technical Parameters

| Model:ZDY1.5 | Filter belt width (mm):B=1500mm |

| Capacity (m3/hr):Q=8-15m3/h | D.S. Dried Sludge (kg/h):110-200kgds/hr |

| Sludge cake moisture content (%):75-85% | Press section filter belt speed (m/min):1-7m/min |

| Motor power:1.85kw | Motor protection grade:IP55 |

| Motor insulation level:F | Power:380V,50HZ,3 |

| Flushing quality (m3/hr):15m3/h | Flushing pressure (MPa):0.6Mpa |

| Gas cylinder pressure:0.45Mpa | Speed control mode of driving mode:Frequency control |

Specification & Model Data

Product Details

Project Site

Product Introduction

BOEEP belt press dewatering machine has two part. One part is the pre-thickening part is a rotary drum, which has the function of concentration. The other part is belt press part, which completes the dehydration task. This machine is mainly used for processing the sludge which is not concentrated in the thickening pool (such as A/O residual sludge).

Structure & Working Principle

Features

The principal part adopts stainless steel as its material and possesses high strength for it is rust-less.

The filter cloth imported from Germany, which provides the best performance and long service life.

Automatic cylinder deviation correction system effectively prevents filter cloth deviation. The safety alarm device and limit deviation controlling improve filter cloth life and reduce maintenance costs.

Great product capability, good washing effect, flexible operation, low containing moisture in cake.

Low energy consumption, high efficiency, low revolutions, low noise.

Safety system monitors the entire working environment, and automatic stopping devices satisfies the need of operation security.

Technical Parameters

| Model:ZDY1.5 | Filter belt width (mm):B=1500mm |

| Capacity (m3/hr):Q=8-15m3/h | D.S. Dried Sludge (kg/h):110-200kgds/hr |

| Sludge cake moisture content (%):75-85% | Press section filter belt speed (m/min):1-7m/min |

| Motor power:1.85kw | Motor protection grade:IP55 |

| Motor insulation level:F | Power:380V,50HZ,3 |

| Flushing quality (m3/hr):15m3/h | Flushing pressure (MPa):0.6Mpa |

| Gas cylinder pressure:0.45Mpa | Speed control mode of driving mode:Frequency control |

Specification & Model Data

Product Details

Project Site